Technical Diagnostics Mastery: Contemporary Vehicle System Analysis

Technical Diagnostics Mastery: Contemporary Vehicle System Analysis

Blog Article

When it comes to auto repairs, technical diagnostics demand technical skill and precision to effectively diagnose automotive problems. Begin by utilizing diagnostic scanning tools to retrieve Diagnostic Trouble Codes (DTCs) for real-time analysis. These codes help professionals identify potential issues, while adhering to a methodical Eight-Step Diagnostic Process maintains thoroughness. Cross-reference diagnostic data with OEM guidelines and carefully record each step. Pre-repair and post-repair scans are vital for confirming repair accuracy and safety standards. Integration of Technical Service Bulletins (TSBs) streamlines service operations with recent factory updates. By maintaining thorough reports and clear customer communication, you'll be better equipped for executing comprehensive troubleshooting strategies. Explore approaches to improve these operations.

Essential Points

- Modern diagnostics leverage diagnostic scanning tools to pinpoint and assess automotive problems through DTCs.

- The 8-Step Diagnostic Methodology guarantees structured and complete vehicle troubleshooting and repairs.

- Initial and final diagnostic scans confirm component performance and enhance maintenance precision and reporting.

- Technical Service Bulletins (TSBs) offer OEM recommendations for resolving specific vehicle performance issues.

- Regular software updates address protection requirements and improve ADAS features.

Mastering Modern Vehicle Diagnostics

In the realm of comprehending modern vehicle diagnostics, it's essential to understand the sophisticated integration of modern systems and traditional inspection methods that characterize the process.

It's clear that the foundation of diagnostics lies in advanced tools like OBD-II scanners. These tools connect directly with your vehicle's onboard computer systems, offering real-time data monitoring, component testing capabilities, and also module programming functionality. They range from basic code readers to sophisticated equipment capable of detailed analysis.

Comprehending Diagnostic Trouble Codes (DTCs) is essential. Each DTC reveals specific information about your vehicle's issues. The first character shows the affected system, such as the Powertrain or Body. The second digit indicates if the code is generic or manufacturer-specific, while the remaining digits locate the fault and subsystem.

Don't underestimate the power of visual inspection, which supports electronic diagnostics. Checking for visible issues, fluid conditions, and component wear can verify electronic findings and highlight additional issues.

This synthesis provides a comprehensive diagnostic approach, empowering you to identify problems correctly and swiftly. By unifying these approaches and systems, you effectively harness the full potential of modern vehicle diagnostics to maintain ideal vehicle performance.

Professional Diagnostic Procedures and Recommended Practices

To effectively handle the challenges of vehicle diagnostics, it's essential to follow the Eight-Step Diagnostic Process, ensuring complete pre-scan and post-scan procedures.

Integrate Technical Service Bulletins (TSBs) to obtain manufacturer-specific resolutions, while meticulous documentation and record keeping streamline future reference.

Maintain clear customer communication to set realistic expectations and offer transparent updates on maintenance developments.

The Eight-Step Diagnostic Approach

Initiating the Eight-Step Diagnostic Process guarantees a methodical and accurate approach to vehicle diagnostics.

Initially, validate the issue by speaking to the client and noting exact problems, ambient factors, and when the condition manifests with a hot or cold engine. A visual inspection proceeds, where you evaluate components, prior maintenance, and check vital fluids, electrical systems, and fuel delivery.

Subsequently, connect diagnostic tools to obtain trouble codes, studying patterns and frequencies for insights. Remember to review technical service bulletins; they provide crucial details on common problems, safety notices, and technical updates.

Analyze scan tool data by examining real-time parameters and measuring them to manufacturer specifications, detecting any abnormal parameters. This analysis helps you to narrow down the problem, focusing on it to a precise area and pinpointing affected components.

Execute repairs, adhering to manufacturer guidelines. It's essential to address the underlying issue, not just the symptom, making sure you service components as needed.

Lastly, confirm the repair by test-driving the vehicle, looking for new issues, clearing codes, and ensuring all systems are operational.

Record all stages, from original problems to end results, and keep clear interaction with the client throughout the diagnostic journey.

Understanding Scan Procedures: Before and After

Recognizing the critical nature of pre-scan and post-scan processes in modern vehicle repair is vital for maintaining both safety and repair standards. A pre-scan analysis acts as your first line of defense, analyzing electronic systems to detect present concerns, fault codes, and concealed damage that cannot be visible during a visual inspection. This comprehensive assessment enables you to identify safety system issues and interconnected component complications, providing a guide for effective repairs.

When the repair work is done, a post-scan check is essential. It ensures that all systems are functioning correctly and validates that no new issues have developed. This step doesn't just validate the success of the repair; it logs system functionality and confirms proper calibration, delivering a clear confirmation of repair completion.

Including these scans into your workflow strengthens safety verification by verifying that all electronic systems, essential for modern vehicle operation, are working as intended. It also expedites insurance claims management, providing faster authorization and more exact repair estimates.

Implementation of Technical Service Bulletins (TSBs)

For effective automotive maintenance, implementing Technical Service Bulletins (TSBs) into your diagnostic procedures is fundamental towards efficient and accurate troubleshooting. TSBs function as essential guides, delivering manufacturer-issued instructions for addressing non-safety-related vehicle issues influencing vehicle performance and client satisfaction.

Your approach should start with a thorough review of appropriate TSBs before commencing diagnostic work. This ensures you have access to manufacturer-specific information about common issues.

Implementing contemporary diagnostic systems, which seamlessly incorporate TSBs, enhances your problem-solving approach. When you obtain diagnostic trouble codes, these platforms allow you to access relevant bulletins, eliminating trial-and-error approaches.

Make sure you adhere exactly to the manufacturer-recommended repair procedures detailed in the TSBs. This accuracy assures that repairs meet the highest standards and support consistent quality.

Experience shows that integrating TSBs minimizes your diagnostic time substantially, as they offer standardized repair procedures and essential tools and materials. This not only boosts technician productivity but also elevates overall customer satisfaction.

Record Keeping and Documentation

Comprehensive record-keeping in automotive repair is vital in maintaining high standards and maintaining legal compliance. First, you should meticulously record car details such as the vehicle identification number, manufacturer, model, and odometer reading.

Record vehicle and owner information to create a thorough profile. During repairs, document all diagnostic test carried out, together with test outcomes and diagnostic trouble codes.

Clearly note parts replaced or repaired and service procedures completed. It's important to log important steps to document the service timeline precisely.

Implement computerized documentation tools through specialized service management programs to streamline record-keeping. Electronic inspection sheets and digital archiving for scan tool reports enhance efficiency and data security.

Always maintain data backups to prevent data loss. For compliance purposes, retain complete repair histories for no less than 15 months, incorporating customer authorizations and declined services.

Digital and hard copy documentation could be needed, based on legal requirements.

Best Practices for Client Communication

When handling the intricacies of customer communication in automotive service diagnosis, establish a thorough protocol that ensures clarity and precision.

Start with the first interaction: actively listen and keep eye contact while collecting specific details about the car's problems. Communicate diagnostics in simple, non-technical language to ensure customers comprehend the process and feel informed.

Record-keeping is essential. Develop comprehensive records of automotive issues, distinguish between essential and optional repairs, and provide comprehensive estimates including parts, labor, and timelines.

Secure written consent for all repairs and meticulously document customer preferences, including insurance confirmations.

Convert complex technical specifications into layman's terms, avoiding jargon and acronyms. This creates trust and assists customers in making educated decisions.

Employ digital tools by implementing digital inspections, text updates, and online payments, improving transparency and convenience.

Keep customers updated with regular status updates, instant notifications of new issues, and clear timelines.

Establish quality assurance through structured inspections and final checks before delivery.

After service, provide thorough documentation of repairs, future maintenance advice, and warranty information.

Gather feedback through feedback forms and follow-up communications to enhance services. Consistent communication promotes satisfaction and loyalty, leading to long-term success.

Advanced Vehicle Diagnostic Solutions

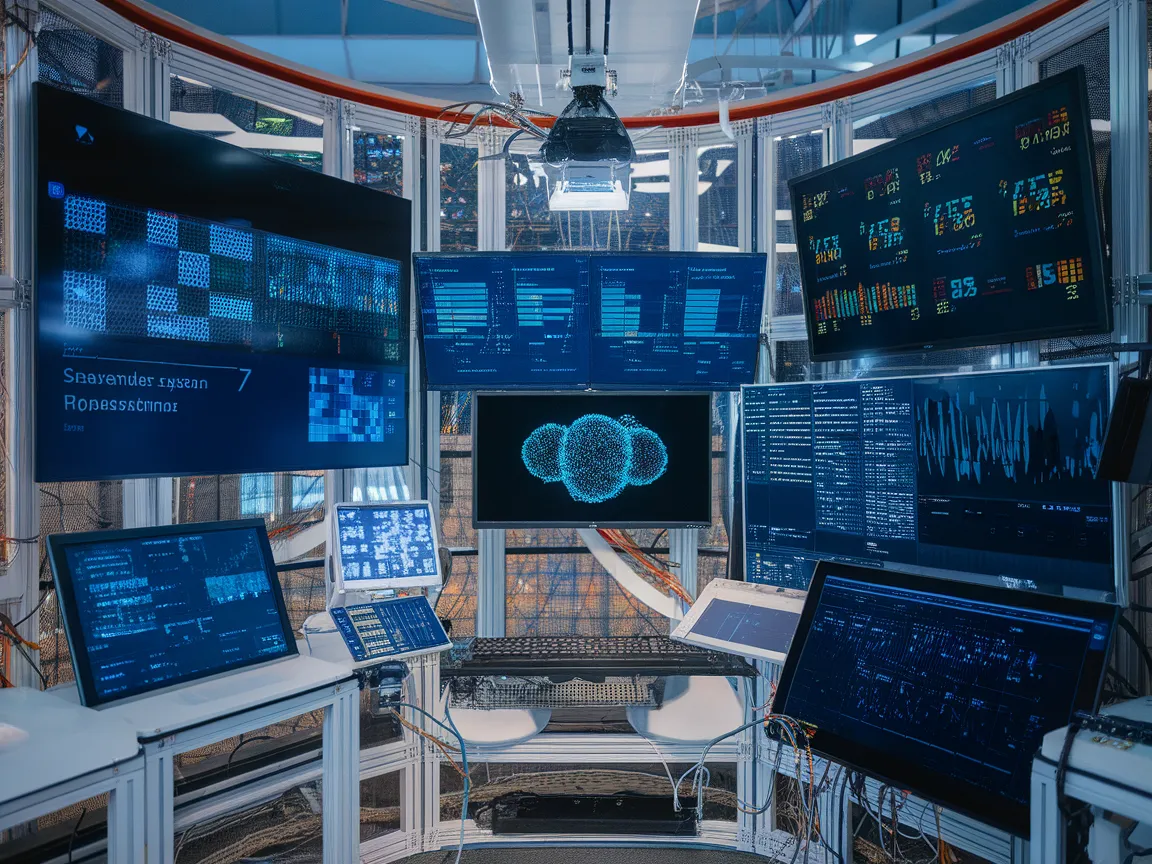

Redefining our approach to vehicle maintenance, advanced diagnostic technologies are reshaping the field of auto repairs. Welcome the future with artificial intelligence-driven systems that slash diagnostic time by up to 90%. By leveraging predictive analytics, you can predict potential failures through thorough sensor data analysis.

Artificial intelligence-enabled visual recognition systems allow for precise damage assessment, while advanced learning systems evaluate extensive vehicle data for precise results. Cloud-based diagnostic systems provide centralized data management across entire fleets. This solution enables automated troubleshooting and instant anomaly detection, enhancing vehicle performance and minimizing downtime.

Remote diagnostics enable you to evaluate vehicle health without physical inspection, delivering live ECU data access, instant fault detection, and proactive maintenance, all while enhancing customer support through remote assistance. Vehicle connectivity and live monitoring track vehicle performance.

These systems continuously measure health metrics, improve maintenance schedules, and analyze driver behavior using GPS-enabled tracking. However, obstacles continue, such as managing underdiagnosis with overly aggressive approaches and the intricacy of error accuracy. As you integrate these advancements, you're going beyond problem-solving—you're advancing automotive excellence.

Advanced Driver Assistance Systems and Current Vehicle Technologies

When servicing vehicles fitted with ADAS, it's necessary to complete both static and dynamic calibration to ensure exact system diagnostics for cameras and radar units.

Stay current on newest programming and software updates to ensure the accuracy of vehicle safety features and adhere to warranty requirements.

Comprehensive logging of these procedures is crucial for warranty compliance and proper safety system verification.

Comparing Static and Dynamic Calibration Methods

A key component of driver assistance systems is maintaining precise calibration, which is performed through either static or dynamic methods.

Static calibration is performed with the vehicle stationary, usually in a controlled environment like a workshop. This requires a level surface, proper illumination, and professional calibration instruments. This technique delivers high precision, but it requires a dedicated workspace and can be time-consuming. It's less flexible and requires substantial facility costs but guarantees predictable performance, not influenced by weather.

On the other hand, dynamic calibration procedures, also known as mobile calibration, is performed while the vehicle is in motion. This process requires clear weather, clear road lines, and particular vehicle velocities. This method offers its flexibility, as it evaluates the system in practical scenarios and requires less dedicated tools. However, it relies significantly on weather and road conditions, and the performance can differ.

Deciding between these methods is based on vehicle requirements, manufacturer requirements, and your service center's capacity. Often, both calibrations are necessary to ensure ideal ADAS performance, specifically after services like glass installations or wheel balancing.

Each method demands professional expertise and must be approached with precision to preserve system integrity.

ADAS Camera and Radar Diagnostics

Today's ADAS-equipped vehicles need careful diagnostic procedures for vision and radar components for flawless operation.

Start by conducting checking all sensors for damage or obstruction. You must check for system error codes which could reveal component issues or positioning problems. Verify the placement of all components based on OEM requirements.

Cameras are fundamental in detecting objects, lanes, and signs, despite having some restrictions. Poor weather could affect functionality, while dirty lenses or low light can hinder operation. Manage these challenges with proper maintenance protocols.

Radar systems utilize radio waves to measure distance and velocity. These systems perform well during challenging weather, but may experience environmental interference. Monitor closely for calibration variations.

For proper diagnostics, utilize both static and dynamic alignment techniques with specialized equipment. Dynamic testing ensures correct functionality on the road.

Always ensure factory-authorized training and employ correct testing equipment. Scheduled maintenance with position checks and component maintenance is essential for continued system effectiveness.

Vehicle Software Management and Programming

In today's evolving automotive landscape, maintaining current vehicle software is vital for peak performance, particularly regarding ADAS systems. Contemporary automobiles are intricate systems containing over 100 million lines of code, making software updates and programming critical for best operation. Software updates address security vulnerabilities, provide feature enhancements, and optimize ADAS functionalities.

You must coordinate these updates through secure protocols using encryption, guaranteeing compatibility across electronic control units. OTA updates simplify this procedure, allowing efficient integration of security patches and feature enhancements without requiring a visit to the service center. Verification and authentication protocols are crucial to guarantee that updates are authentic and compatible with your vehicle's systems.

The software architecture encompasses core stacks like time-based software for essential functions and event-driven software for user interactions. Understanding integration points, such as system abstraction layers and middleware frameworks, is crucial for effective system diagnostics.

Live monitoring and error identification enhance diagnostic capabilities, while system optimization and calibration control are crucial for maintaining ADAS efficiency.

Verifying Safety Systems

Today's automobiles rely heavily on software to perform optimally, and managing updates effectively is a single component in the equation. You should concentrate on verifying the safety systems within ADAS and contemporary automotive platforms to ensure peak performance.

ADAS integrates high-performance computers, sensing systems, and actuators to enhance driving safety. Its essential systems include location tracking, environmental sensing, and operational systems created to reduce incidents by minimizing human errors.

To validate these systems, start with requirements-based testing. Define safety goals, confirm functionality, and verify all elements are documented.

Next, utilize scenario-based testing, modeling dynamic traffic situations and weather situations to assess system responses.

For hardware, implement Hardware-in-the-Loop (HIL) testing, connecting real components to verify sensors and controllers. Augment this with computerized simulations, modeling real-world conditions for a comprehensive pre-deployment check.

Active safety features like emergency brake assistance and adaptive cruise control require meticulous validation.

Remember to verify passive safety features, such as warning systems and indicators, verifying they're reliable and effective.

Warranty Implications and Documentation

The integrity of warranty protection for ADAS-enabled vehicles depends heavily on comprehensive record-keeping. It's crucial to guarantee that each ADAS component service and repair is meticulously documented. Service documentation need to specify calibration procedures, replaced components, and diagnostic protocols. Before and after service diagnostic scans are crucial, as they document your vehicle's status throughout the service process.

Due to ADAS system connectivity with critical vehicle systems like critical driving components, all repairs demand careful consideration of this interconnectivity. Detailed calibration records is critical, as even minor repairs can impact ADAS functionality, demanding accurate calibration.

Technician credentials constitute a vital consideration. Ensure that your repair center documents of technical training specific to ADAS components. Following manufacturer guidelines and using authorized equipment is crucial for protecting warranty validity.

For quality control, log system operation through computer-based diagnostics and, where safe, professional road tests. Log initial issues, assessment outcomes, service approvals, and completion verification.

Keep both soft and hard copies of all documentation to function as verified records, protecting against potential warranty disputes and maintaining thorough warranty administration.

Future Trends in Vehicle Diagnostics

The automotive diagnostic field is experiencing a revolution through innovative technologies that address the complex challenges of maintaining modern vehicles. Smart diagnostic systems is at the forefront, offering live component tracking for parts performance and intelligent monitoring that pinpoint issues ahead of breakdown. These technologies enable automated diagnostic processes, securing maintenance procedures are both efficient and effective.

Cloud-based solutions are revolutionizing remote diagnostics, enabling unified information control. This facilitates complete fleet surveillance and analysis, optimizing maintenance schedules across multiple vehicles.

In the domain of electric vehicles, specialized diagnostic tools are necessary. Energy storage assessment, comprising power transfer evaluation and thermal management, plays a key role in maintaining EV performance.

Connected car diagnostics additionally improve instant system assessment through networked diagnostics, delivering remote system upgrades and seamless data transmission.

Intelligent processing systems, such as systematic error identification and natural language processing, provide intelligent diagnostic recommendations, anticipating failures with precision.

Advanced solutions like mixed reality systems offer visual service support and live assistance. Modern detection systems upgrade data collection capabilities, creating a predictive service framework.

These innovations secure vehicles remain reliable, reducing operational expenses and interruptions.

Fundamental Diagnostic Tools

Mastering essential diagnostic equipment is crucial for those engaged in modern automotive maintenance. You'll need to get comfortable using OBD-II scanners and code readers, as these are the foundation of automotive troubleshooting.

High-end scanners like various top-tier diagnostic tools deliver thorough diagnostics and real-time monitoring. When cost is a consideration, basic code readers like affordable diagnostic tools deliver fundamental diagnostic capabilities.

Enhance your diagnostic capabilities with digital oscilloscopes and multimeters, essential tools for measuring electronic signals. Look for tools with bandwidth up to 100MHz, multiple channels, and data logging features. Integrated waveform generators facilitate system Professional Development and Training diagnostics effectively.

Include OEM diagnostic solutions. Applications like professional diagnostic software allow for multi-manufacturer diagnostics, critical for modern vehicles. Furthermore, professional calibration tools from industry-leading manufacturers guarantee precision in your diagnostics.

Keep your diagnostic tools regularly. Periodic maintenance expand vehicle coverage, resolve software issues, and upgrade diagnostic capabilities.

This systematic approach, integrating modern tools and accurate diagnostics, will optimize repairs and promote proper vehicle maintenance.

Technical Training and Professional Advancement

Within today's advancing automotive industry, maintaining competitiveness requires embracing continuous professional development and training. The field's requirements are evident: to stay current with advancing vehicle technologies, you must participate in ongoing education and skills enhancement. ASE certification maintains a standard, requiring recertification every five years through rigorous testing and documented experience.

Focus on fundamental aspects like powertrain maintenance, drivetrain components, and complex electrical systems to maintain your expertise.

Improving your technical proficiency necessitates honing troubleshooting skills, diagnostic procedures, and competent operation of modern diagnostic equipment. OEM training programs are invaluable, offering in-person training, online courses, and field experience, all designed for particular vehicle brands.

Prerequisites for these programs typically include a high school completion, formal automotive education, and a valid copyright.

Leverage online resources such as CarCareKiosk and the ASE E-Learning Portal for adaptable learning options. Obtain technical documentation through platforms like industry-standard databases to keep updated with OEM repair procedures.

Industry certifications are means of professional growth, with advanced credentials like Master Technician status demonstrating your comprehensive knowledge in automotive diagnostics and repairs.

Quality Management and Validation

The significance of quality control in automotive repairs cannot be overstated, as it guarantees that each car departs the facility in peak condition.

Repair confirmation initiates with a meticulous visual inspection to verify that repair areas fit perfectly and everything is properly fastened. Technicians should perform mechanical testing, comprising functionality checks and road tests, to verify service quality. Employing diagnostic tools is essential for validating operations.

Safety validation remains paramount; a thorough multi-point safety inspection ensures all systems comply with manufacturer standards.

Accurate record-keeping forms the foundation of quality assurance. Digital Vehicle Inspection Reports should feature thorough evidence of repairs, utilize color-coded problem classification, and contain comprehensive technician notes. Log all parts, procedures, and diagnostic findings to ensure a transparent service history.

Client communication plays a vital role in satisfaction. Carefully detail repair procedures, using visual aids and sharing preventive maintenance tips. Walk through documentation, explain warranty terms, and address any inquiries.

Guarantee adherence requires complying with manufacturer procedures and implementing approved parts to protect coverage.

Create follow-up procedures with validation measures, collect feedback, and maintain comprehensive records to enhance service quality and customer satisfaction.

Essential Questions Covered

How Can I Discover a Dependable Auto Repair Shop Near Me?

Initialize by researching online reviews and ratings. Check services like Google Maps or Yelp. Check qualifications including ASE. Request recommendations from trusted sources. Verify they include troubleshooting services. Check service guarantees and warranty coverage for customer protection.

Exploring the Expenses Related to Vehicle System Analysis

For automotive diagnostic services, you'll need to consider various costs including labor charges, diagnostic tool fees, and computer diagnostic charges. Initial diagnostic scans typically range from $50-$150, but more complex issues can lead to additional charges. You should ask your mechanic to detail every expense, following industry-standard testing protocols.

When Should I Schedule a Diagnostic Test for My Car?

It's recommended to conduct a diagnostic test biannually to keep your vehicle running at its best. Keep track of engine codes, sensor outputs, and system calibrations. This preventive strategy spots developing concerns, ensuring timely repairs, minimizing breakdown risks, and ensuring peak vehicle operation.

Can I Perform Basic Car Diagnostics Without Professional Tools?

Absolutely, you're able to perform basic diagnostic checks by yourself. Use an OBD-II scanner to diagnose fault codes. Test battery voltage by employing a voltage meter. Examine all fluids by yourself. These steps assist in finding possible concerns with home diagnostics.

Are Diagnostic Tests Included Within Vehicle Warranty or Insurance Policies?

You need to examine your insurance policy and warranty documentation. Warranty coverage may include diagnostic tests when they're related to covered repairs, but insurance typically doesn't cover diagnostics unless specifically tied to an covered insurance claim.

Summary

You've examined the intricacies of modern vehicle diagnostics, highlighting the critical nature of expert methodologies and state-of-the-art technologies. By understanding ADAS and evolving vehicle systems, you're equipped to tackle future diagnostic challenges. Utilize advanced tools and maintain developing your skills through professional development. Emphasize quality control and verification to deliver precise outcomes. As the automotive landscape progresses, your dedication to mastering diagnostic techniques will enable you to solve problems efficiently and safeguard vehicle integrity.

Related sources: https://www.sae.org/standards/automotive

Report this page